This website uses cookies to ensure you get the best experience on our website. Learn more

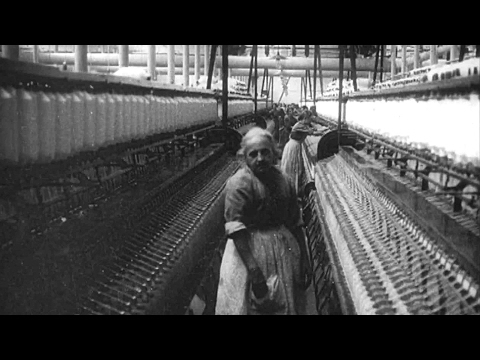

Queen Street Mill Textile Museum

Queen Street Mill is a Grade I listed building. in Harle Syke, a suburb to the north-east of Burnley, Lancashire. It was built in 1894 for the Queen Street Manufacturing Company. It closed on 12 March 1982 and was mothballed, but was subsequently taken over by Burnley Borough Council and maintained as a museum. In the 1990s ownership passed to Lancashire Museums. Unique in being the world's only surviving operational steam-driven weaving shed, it received an Engineering Heritage Award in November 2010. Previously open to visitors and offering weaving demonstrations, the museum closed in September 2016 . In April 2018 Lancashire County Council announced that the museum, along with Helmshore Mills Textile Museum and the Judges Lodgings in Lancaster, would reopen three days a week.

Continue reading...

From Wikipedia, the free encyclopedia.

Continue reading...

From Wikipedia, the free encyclopedia.

Attraction Location

Queen Street Mill Textile Museum Videos

More Attractions in Burnley

-

Big Window Burnley

-

Burnley Mechanics

-

Cliviger Fish Ponds

Cliviger Fish Ponds

-

Crow Wood Leisure Limited

-

Doorsteps

Doorsteps

-

Four Alls Inn

-

Ighten Leigh Social CLub

-

Kiddy Chaos

-

Liv Spa

-

MFA Bowl Burnley

-

Moorhouse's Brewery

-

Pegasus Drop Zone

-

Prairie Sports Village

-

Reedley Marina

-

Reel Cinema

-

Salon Twenty Seven

-

Shores Hey Farm

-

St Peter's Church

-

The Bridge Bier Huis

-

The Mix Cafe Bar and Nightclub